How data is transforming railway maintenance

Our railway industry doesn’t always showcase the pioneering technologies we use as much as it could, often cloaking the exciting innovations we work on under acronyms that the public find hard to understand. When it comes to the rail network’s use of data, this is particularly clear – ask a member of the public what remote condition monitoring is and it’s quite likely that you would receive a blank stare.

Yet, the rail network’s use of data is one of the key areas which could transform how we travel, how work is conducted and the entire industry.

So, for this edition of Innovation of the Month we have taken a look a just a handful of exciting projects which show great collaboration across the sector, to harness data and digital technology. This includes a joint project between Network Rail, an operator, a large asset owner and an SME, as well as the exciting work one recent market entrant is doing in this space.

We hope you enjoy!

The Seasonal Intelligence Platform - An example of whole-industry collaboration

Kicking off this edition is a fantastic example of collaboration between suppliers – a major client and a train operating company – who have partnered to create a tool to manage track adhesion (the friction between the train wheels and the rail).

The project was launched by Network Rail Southern Region and rolling stock asset manager Porterbrook in 2019, and has since brought in Govia Thameslink Railway (GTR) who operate the Southern franchise, as well as SME, Route Reports.

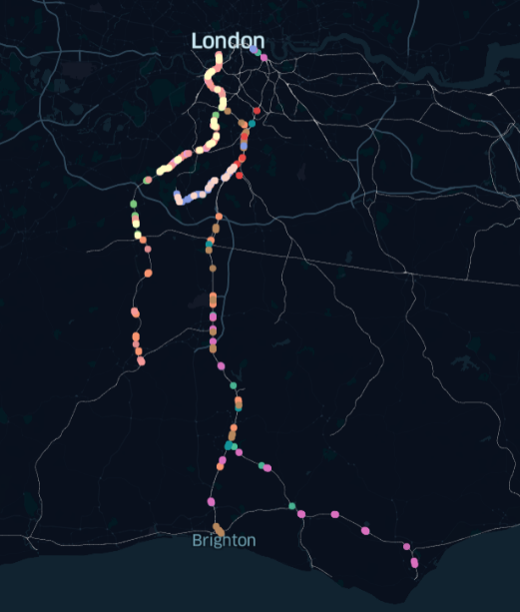

[Image right: Snapshot of adhesion issues experienced by passenger trains]

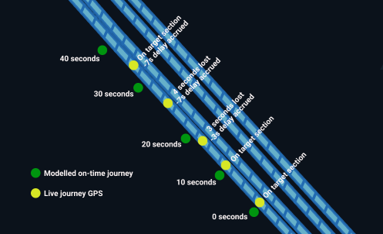

The project aim was to explore how train data can tackle challenges that arise every Autumn – whereby leaf contamination on the railway lines causes trains to accelerate and decelerate more slowly, severely impacting performance and potentially resulting in major safety incidents. Speaking to Network Rail Southern Project Manager, Dan Bannister, he explained their focus was on utilising on-train data to identify where problems are arising before an incident occurs. He says that the information is utilised to direct Network Rail’s fleet of water-jetting trains, which clear the rail of leaf contamination using high pressure water.

They began with Porterbrook’s ‘data-rich’ Electrostar trains to automatically monitor where adhesion issues lead to lost time for Southern passenger services during the Autumn months. This provides an incredibly rich dataset in support of drivers manually logging when and where they experience issues.

[Image left: Example mapping of adhesion issues causing delays]

The group created a digital map to pinpoint where issues arise which result in the late running of trains for passengers. This map enables users to plan with a great deal of accuracy which track and specific line needs treatment – crucial for areas with complicated layouts such as around Clapham Junction.

Using the map, Controllers at Network Rail Southern Region are then able to accurately deploy the water-jetting trains to treat the right lines at the right times. Dan explained that their fleet carry out 336,000 miles of water jetting per year – the equivalent of going around the world 13 times – with some areas covered up to 4 times a day. Every mile of this treatment is recorded within the platform thanks to GPS trackers installed on the water-jetting trains by Route Reports.

Currently, predictions of adhesion problems and decisions to treat the track are made based on driver reports of conditions and weather forecasts. The tool allows NR to understand leaf-fall issues more accurately, and mitigate related challenges. In 2020, as soon as water-jetting trains ceased to run, the passenger fleet began to report more adhesion problems in the system, indicating to the team that some locations were still experiencing issues whereas the majority of the network was now safe for normal operation.

[Image right: One of NR Southern’s water-jetting trains.]

Dan added: “It allows Network Rail to consider the network holistically and to take a risk-based approach. Instead of deploying resources solely based upon a forecast, we can respond to emerging threats which we would otherwise be unaware of.”

Speaking at our recent Unlocking Innovation event, Porterbrook’s Head of Digital Services Stephanie Klecha revealed the team affectionately refers to the tool as the ‘hungry caterpillar’. Stephanie stressed it is not just a “fancy front end tool”, but that there is a lot of data that can be harnessed and the benefits could potentially be felt by all parties:

- For the rolling stock leasing company, like Porterbrook – reducing wheel slip reduces the risk of damage and extends the lifetime of trains

- For Network Rail – it gives a greater understanding of when Autumn runs from and to, enables more accurate deployment of resources, reduces unnecessary water jetting treatment, and provides greater information about the network

- For operators, i.e. GTR – saves time and improves reliability – helping reduce Autumn-related delays which can cost up to £20 million per year – and increases driver confidence

It allows Network Rail to consider the network holistically and to take a risk-based approach

Dan Bannister, Network Rail

As it stands, Dan said there is good coverage of Sussex with the technology due to be expanded to Thameslink and Great Northern lines, resulting in increased coverage in Kent, Wessex and lines north of London.

And looking to the future, Porterbrook is optimistic that this model can be scaled up across the network. Stephanie explained they intend to provide access to the information on a subscription basis for infrastructure teams and the industry to make the most of. It is great to hear Porterbrook take such an open and collaborative approach!

How One Big Circle is changing the game.

We also wanted to share the work of a rising SME which has brought innovative technology from another sector into rail, and is at the frontier of collecting data on the railways. One Big Circle (OBC),

relative newcomers to the industry, have worked with Network Rail and Transport for Wales (TfW) to roll out their Automated Intelligent Video Review (AIVR).

According to Emily Kent at OBC, it is in effect a ‘Google Earth’ for rail, but with updating imagery. A camera is installed inside the windscreen, or in the Tail Lamp bracket housing, of any measurement or operational vehicle. It automatically captures video data and telemetry whilst on the move. Rail professionals can see ‘what the train sees’ – capturing critical lineside video data, with location, measurement, mark-up and sharing tools.

In Wales specifically, One Big Circle works with TfW Driver Managers and Trainers directly so they deploy the devices to collect data and then TfW, Network Rail and their contractors can access the data and use it for multiple purposes across many disciplines.

One of the most exciting features of the platform is that it uses advanced machine learning to understand what the images show and gather further insight into the train’s surrounding environment. This means that rail professionals can use the tool to monitor and assess any anomalies to the railway environment, detect assets and people or vegetation growth and so on, as a direct result of rail use, and can make informed decisions on how to counteract this.

By having access to the cloud-based footage and alerts, before putting boots onto the ballast, they can ensure that the team has the information it needs to prepare the correct tools and ensure that they have safe access established before heading out trackside. All of this comes together to ensure the process is safe, as well as greatly increasing the efficiency and effectiveness of lineside vegetation management works.

[ For a great example of what the AIVR camera sees,

watch this recent video from Network Rail using AIVR! ]

One Big Circle’s Emily Kent [pictured] told us: “In the relatively short space of time we have been working within rail it’s been really exciting to see the pace of innovation and collaboration, and by working closely with industry innovators in an iterative process we first and foremost ensure our technology meets their need and delivers rapid results – both current and long term.”

In a recent article, Rick Fisher, Transport for Wales’s Seasonal Planning Manager, was quoted: “[Using this technology], it meant that we could undertake that work quickly and redeploy our AIVR device down the line to check work had been completed and feed that back to our driver colleagues.

“AIVR provided us with a range of different solutions, including rapid access which can be quickly shared with the right people, machine learning models to automate the process of identifying high-risk sites, plug and play solutions which can be used across our entire fleet and data, including the metadata, fed into reports that can be shared with the wider business.”

If you want to hear more about innovative examples of data collection in the industry, catch up on our most recent

Unlocking Innovation event on our website here. The event heard examples of the use of UAVs, thermal cameras, satellite radar and a host of other exciting projects!

As ever, your feedback is welcome. Please send any comments or questions to Alexis King at

[email protected].

Also, don’t miss our Unlocking Innovation Zone event at Railtex / Infrarail 2021, with short talks on a wide range of exciting areas!

Find out more and register here today.