Showcasing some of the best in rail innovation ahead of the RIA Innovation Conference

For this edition of the Innovation of the Month, we have taken a look at some of the main challenges and opportunities in rail innovation, which the event will look to cover.

The Conference is one of the key innovation events in the calendar, and comes at a pivotal time for our industry. As a sector, we need to make the case for rail innovation. That includes highlighting the exciting projects already being done and the benefits – for decarbonisation, reliability, accessibility, passenger experience and much more. But it also means being honest about how we can innovate better and faster. As many of you will know, despite some excellent work, there remain some critical barriers to getting innovations onto the railways.

So for this feature, and breaking from the format of previous editions, we had the pleasure of speaking to Ricardo Rail’s Innovation lead, Jonathan Brown, who highlighted the opportunities and challenges around decarbonisation. We also spoke to Porterbrook’s Stephanie Klecha about the fantastic work her team are doing to reshape how suppliers and customers can collaborate to improve reliability, as well as what needs to be done across the board.

I hope you enjoy!

Interview with Jonathan Brown, Ricardo Rail

Speaking to Jonathan Brown, Technical & Innovation Engagement Lead at

Ricardo Rail, he explained that it is important to address what exactly we mean by innovation – “There is often much misunderstanding with many thinking that innovation must mean something new and exciting, but it simply means making a change which provides a new value.”

He explained that the first zero carbon train was in fact developed in the Scottish Highlands in the 1950s, with the train being converted from diesel to electric battery and powered by electricity from North of Scotland Hydro Electric Board. However, the value of a zero carbon train at the time was not recognised and it was later removed from service.

Looking at value for the railway sector today, Jonathan argued that we need to look to other industries where changes and technologies have brought impact and how that might be brought to rail. This underpins much of what Ricardo Rail does, with the origins of the company in the automotive sector, first established over 106 years ago by Harry Ricardo.

Now based at a state-of-the-art facility in Shoreham, Jonathan explains that since their inception they have sought to be as innovative as possible, particularly focusing on engine technology and traction power for trains. Using their experience in the automotive sector, Ricardo is now involved in a range of rail projects.

One interesting example is the recently announced

SWIFT Express Freight Train (pictured left), in partnership with Eversholt, ‘to transform a passenger train into a low-carbon option for transporting parcels directly into urban centres’. The Swift train will be a Class 321 EMU capable of holding up to 12 tonnes of parcels per car and operate at speeds of up to 100mph, As Jonathan highlighted the concept is not new - parcel freight trains were used decades years ago, with parcel yards once being a common sight at every station however they have steadily been phased out of the industry. The new value derives from the changing nature of demand and business – e-commerce and domestic parcel distribution.

Another is their approach to remote testing on the

Alstom TRAXX 3 MS (the only multi-system locomotive with the last-mile functionality - pictured right), through which they managed to conduct remote testing with customers in different countries, due to the COVID-19 restrictions. Using a live web-based testing environment, they enabled customers in the

Netherlands and the Ricardo Utrecht team to monitor the tests being undertaken at the Velim test centre in the Czech Republic.

When asked to look to future opportunities for rail, he was clear that the most important issue will be to decarbonise. From changing cultures and behaviours to new technologies, he stressed there was a lot of work to do. This includes decarbonising traction power, but also fundamentally means reducing the amount of energy rail requires, by making maintenance and construction far more efficient, for example.

He says that decarbonisation needs to be treated in the same way the industry has come to treat safety - “The last 200 years have been driven by getting people from A to B safely and on time. But now sustainability must be a key priority.” However, the biggest barrier is a lack of business case for decarbonisation, emphasizing that “Right now there is no framework for people to fully decarbonise as it becomes expensive and uncompetitive.”

“The last 200 years have been driven by getting people from A to B safely and on time. But now sustainability must be a key priority.” Jonathan Brown, Ricardo Rail

And finally, we ended by asking what he enjoys most about working in rail. His answer - the opportunity to bring people together, with rail being “a public and social good, and an environmental good.” We couldn’t have put it better ourselves.

'Darting forward'

For this edition we also spoke to

Porterbrook’s Head of Digital Services Stephanie Klecha about the

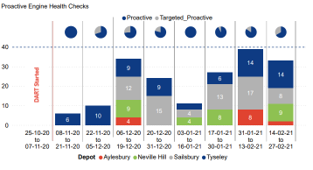

Data-to-Action Reliability Taskforce (DART) she is leading. Launched in November 2020, it is a collaborative innovation project led and funded by Porterbrook in partnership with Wabtec and Unipart Rail. The project came about following discussions between Porterbrook and the Department for Transport (DfT) on how the asset owner could actively support Train Operators (TOCs) in delivering improved engine reliability - specifically reducing DMU engine related delays by 60% across the rail network; covering 6 TOCs, 7 Diesel Multiple Unit (DMU) fleets, across a full 13 periods.

As Stephanie explained, Porterbrook have supported their TOC customers be creating embedded depot teams, using data analytics, to mobilise targeted interventions on engines which are at highest risk of failure. The teams on the ground are also able to respond quickly to any failures. So far, it has been focused on Turbostar units and Class 158/159s, operated by Cross Country, West Midlands, East Midlands, South Western, Chiltern and Northern railways.

The ultimate aim of the project is to align goals of supply partners and customers, to move away from reactive to proactive engine interventions based on data-driven insights.

Stephanie was clear about the importance of shared risk between suppliers and customers. As it stands, and conversely, there is no clear financial incentive case for the supply chain to invest in such extensive proactive monitoring. Given this, the team at Porterbrook has sought to ensure everyone is aligned towards positive outcomes from the project – taking on some risk itself and currently operating at cost – to build a business case for such an approach.

“Once you devolve risk and everyone has some skin in the game, you can align goals.” Stephanie Klecha, Porterbrook

It’s clear that it is an innovative approach to the supply chain and TOC relationships. Whilst this has its challenges within the complex structure of the UK rail industry, the project team aims to prove that this collaborative approach can yield benefits for each party individually and the industry as a whole.

Looking ahead, although the initial DART focus is on engine reliability, if the initiative proves successful, Porterbrook will go on to look at applying this approach to other high impact subsystems. According to Stephanie, this will further improve reliability, availability and efficiency within the industry.

And on innovation more broadly, Stephanie echoed what Jonathan said, emphasising that it is not just a new piece of kit or data on its own that will change things, it requires innovation in hardware, software and processes to upgrade the UK rail network. She explained: “Innovation in one area alone is unlikely to unlock the potential needed for our industry’s ambitious targets”.

[Image - Sample data on the number of proactive engine checks conducted by DART, across the depots. Data from Nov 2020 – Feb 2021]

She further stressed the crucial role innovation has to play, with the example of DART using a new approach to develop commercial models that incentivise performance throughout the supply chain. It is also highlighting the process and training innovation required to realise tangible value from existing and emerging technologies.

Ending on the same question of what is most exciting about working in rail innovation, Stephanie answered: “I am most excited about the innovation to connect multiple players and suppliers to deliver progression in rail as a collaborative system.”